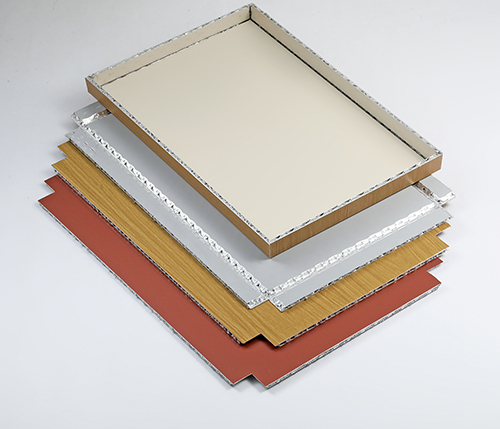

Surface treatment of aluminum three-dimensional plates using roller coating,com pared to traditional methods, there will be no color difference in surface treatment,the product color under roller coating treatment is uniform and not prone to fading or discoloration,basically able to ensure a stable and non discoloration effect for 25 years.superior environmental performance and light weight、can produce various color patterns according to design requirements,beautiful and tidy, sturdy and reliable, with strong seismic resistance.

Surface treatment of aluminum three-dimensional plates using roller coating,com pared to traditional methods, there will be no color difference in surface treatment,the product color under roller coating treatment is uniform and not prone to fading or discoloration,basically able to ensure a stable and non discoloration effect for 25 years.superior environmental performance and light weight、can produce various color patterns according to design requirements,beautiful and tidy, sturdy and reliable, with strong seismic resistance.

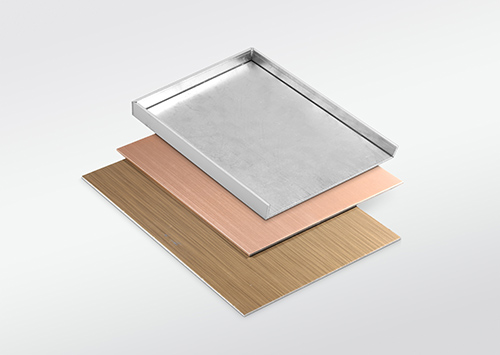

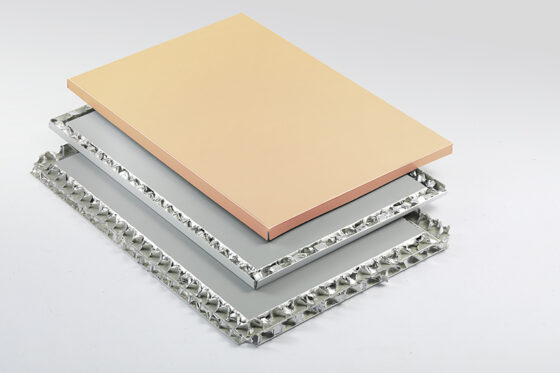

The three-dimensional aluminum composite plate has an excellent rigidity to weight ratio due to its multi-layer composite structure.The uniform distribution of hollow protrusions in the middle layer of the ladder column allows the board to obtain large stress with small weight,and its resistance to wind pressure and bending is significantly higher than that of aluminum-plastic plates and aluminum veneers.Integrated decoration and sound insulation,prefabricated installation,weather durability,and superior environmental performance.Lightweight, can produce various colors and patterns according to design requirements, beautiful and tidy, sturdy and reliable, strong seismic resistance, fire prevention, sound insulation, heat insulation, waterproof and moisture-proof.

The three-dimensional aluminum composite panel combines the advantages of various metal roof wall panels and is suitable for interior wall integrated panels and ultra long special panels in public buildings. It can be installed in a semi arc shape on the top wall, and the product is also suitable for use in places such as ships, carriages, elevators, etc.The board is made of thickened bottom aluminum plate, which has strong impact resistance and can be used for decoration in various high-end public places.

PURFUL Building Materials

PURFUL Building Materials