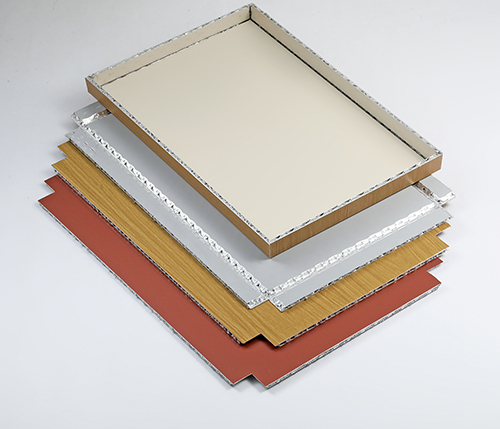

Les panneaux muraux en acier sont composés de plaques d’acier galvanisé à chaud et de plaques de support (plaques de plâtre, Panneau de silicate de calcium, carton ondulé, panneau en nid d’abeille) sous diverses formes. Ils sont faciles à installer, maintenir, Nettoyez la surface, et ont une dureté élevée. Ils sont largement utilisés dans les murs des bâtiments publics tels que les hôpitaux, école, Salles d’affaires, et centres de services.

Composition des panneaux muraux en acier

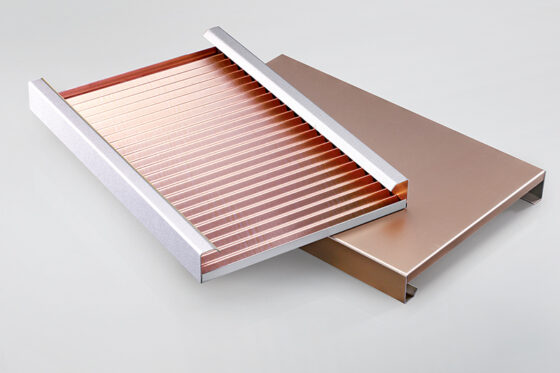

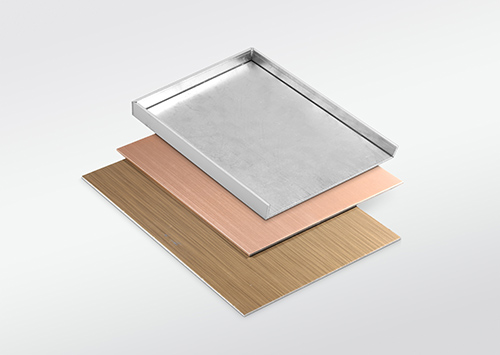

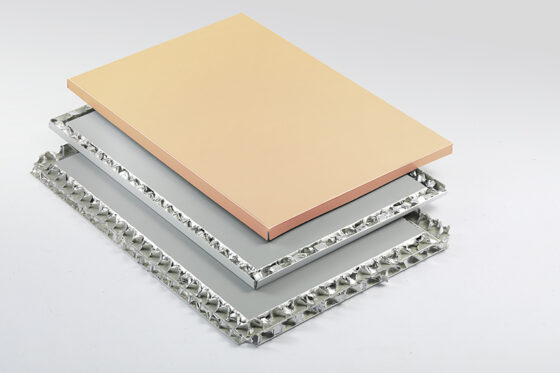

COUCHE DE BASE: La plaque d’acier galvanisé thermofusible est couramment utilisée, avec une épaisseur de 0,6 ~ 0,8 mm. Il est traité par la prévention de la rouille, Prévention de la corrosion, et les procédés de galvanisation à chaud.

COUCHE DE SURFACE: La surface du panneau mural en acier est pulvérisée avec de la poudre électrostatique, ou le processus de revêtement pré-rouleau peut être sélectionné; Pour les exigences de surface du grain du bois, grain de pierre, grain de cuir et autres textures, La technologie d’impression par transfert thermique ou le processus de revêtement de film peuvent être utilisés.

MATÉRIAU DE BASE: plaques de plâtre, Panneau de silicate de calcium, carton ondulé, et des panneaux en nid d’abeille répondant aux spécifications correspondantes doivent être utilisés conformément aux prescriptions de conception.

Texture métallique Éléments de mode

Texture métallique Éléments de mode

Technologie de surface :La surface est principalement divisée en plusieurs types: Revêtement pré-rouleau, Pulvérisation électrostatique de poudre, Impression par transfert thermique, et le revêtement du film.

Avantages du produit : Ignifuge, Résistant aux taches, antibactérien, facile à nettoyer, et facile à entretenir.

Matériaux de construction PURFUL

Matériaux de construction PURFUL